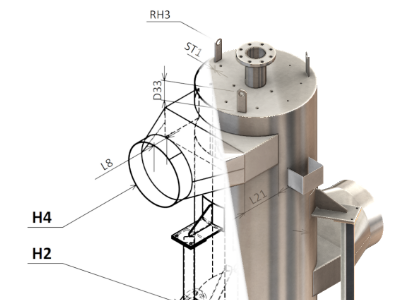

The Shell & Tube heat exchanger according to TEMA standard is made up of a bundle of tubes with one, or two tube sheets in a cylindrical shell, inlet and return chamber and inlet and outlet nozzles for fluids. The heat exchanger design is adapted to the requirements, e.g. both fixed tube plates or one fixed and the other floating tube plate, chambers fitted with flange connection or welded to the shell, etc. The design can be based on a horizontal or vertical position. These exchangers find wide-ranging applications.

VíceHeat exchanger according to TEMA

References

We design and product customized heat exchangers.

Main attributes of heat exchanger according to TEMA:

-

Commonly used and verified concept of heat exchanger.

-

Variable design arrangement of heat exchanger.

Shell & Tube heat exchangers according to the TEMA (Tubular Exchanger Manufacturers Association) standard are established tubular heat exchangers with cylindrical shell and wide range of designs. Manufacturing of heat exchangers according to TEMA is possible with two tubesheets, or with just one tubesheet and u-shape tubes. A version with demountable casing is also possible.

Exchanger according to TEMA can be designed as horizontal or vertical. This type of heat exchanger will find its use as cooler or heater. We deliver heat exchangers according to TEMA to production facilities where their functionality is verified or replacement is required, for ex. in the chemistry industry. If production documentation is not available anymore, we offer measurement of existing exchanger and subsequent recalculating in company's software to design of replacement.

Advantages of heat exchangers according to the TEMA:

-

Low pressure drops.

-

Good cleanability at some arrangements variants.

Disadvantages of heat exchangers according to the TEMA:

- Thermal conductivity coefficient is lower compared to the compact types of heat exchangers (for ex.: heat exchanger type VAKAHEMCE).

- Achieving efficiency at the cost of higher heat transfer surface.

If you have any questions do not hesitate to call us. We will be happy to discuss all of your requirements for the type of heat exchanger according to TEMA.

Link: www.tema.org