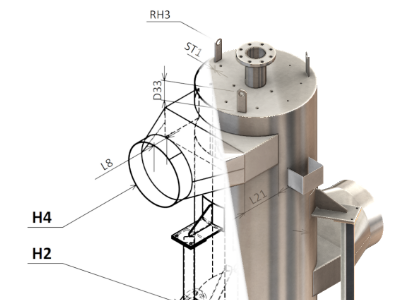

Custom production of heat exchangers type VAKAHEMCE. Main attributes of heat exchanger type VAKAHEMCE:

Because a high countercurrent is secured inside of the body of the VAKAHEMCE heat exchanger, it is included in the category of high efficiency. Another advantage over the other exchangers is the increased heat transfer coefficient is due to the turbulent environment inside the tubes. In the VAKAHEMCE heat exchanger, spiral tubes are used, which give the medium a higher velocity and in addition, dilatation of the tubes is ensured.

This type of heat exchanger can be used as a condensing exchanger or as an evaporator. The feedback on VAKAHEMCE from our clients is very good, when they use it behind the natural-gas boiler as a condensing exchanger, where the temperature difference of 3,9 Kelvin is on flue gases at outlet and water inlet. The feedback on VAKAHEMCE from our clients is very good, when they use it behind a natural-gas boiler as a condensing exchanger, where the temperature difference between the flue gas outlet and water inlet is 3,9 Kelvin (3,9 °C) or in a non-condensing process the difference is 1 Kelvin.

Recommended use of heat exchanger

The heat exchanger type VAKAHEMCE is not primary suitable for heavily polluted flue gases. In this case, structural changes are necessary for this type of heat exchanger, which is interesting for its compactioness and low construction requirements while maintaining high efficiency. To ensure the whole vessel can be deaerated, only vertical position of heat transfer pipes is available for this type of heat exchanger. Orientation of the VAKAHEMCE to a horizontal position is only possible if both media are gaseous.

Advantages of heat exchanger type VAKAHEMCE:

Disadvantages of heat exchanger type VAKAHEMCE:

If you have any questions do not hesitate to call us. We will be happy to discuss all of your requirements for the type of heat exchanger type VAKAHEMCE.