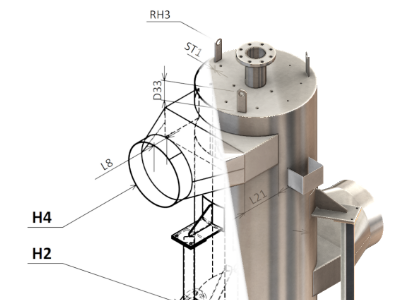

The VAKAFIELD type heat exchanger is made up of a bundle of Field tubes, water chamber, inlet and outlet nozzle and a casing made of sheet-metal components. The Field tube is a tube-in-tube system. This is a very favourable design at high temperatures when tubes can dilate freely, thus preventing damage to tubes due to temperature differences along the tube length. This is used for example as an air cooler.

MoreVAKAFIELD heat exchanger

We specialize in the custom manufacturing of heat exchangers. Main attributes of VAKAFIELD heat exchanger:

-

Good heat transfer cooficient.

-

Easy cleanability of tube surface.

-

VAKAFIELD heat exchanger has low pressure drops.

The Field tube heat exchangers are suitable for applications where good cleanability is necessity due to high appearance fo solid pollution particles, or the tubes needs to be protected against aggresive environment with a plastic coating. Another reason for choosing this type of heat exchanger can be the high temperature of flue gas and the need of free dilatation, which prevents from longitudinal damage of the tube and also damaging weld on tubesheet/tubes.

The Field tube is a tube-in-tube system, that contains two different tube diameters.

VAKAFIELD heat exchangers from our production are mostly situated as flue gas or air coolers, or as heaters of the medium using source's waste heat.

Advantages of VAKAFIELD heat exchanger:

-

Dilatation of tubes at high temperatures.

-

Suitable for applications with pollutants.

-

Is suitable for an aggressive environment with appropriate material grade.

Disadvantages of VAKAFIELD heat exchanger:

- Limited length of tube.

-

Only horizontal orientation of tube bundle is possible.

If you have any questions regarding the design and manufacture of VAKAFIELD heat exchangers, please call us anytime. We will be happy to discuss all of your requirements for the type of heat exchanger according to VAKAFIELD.